Presentation

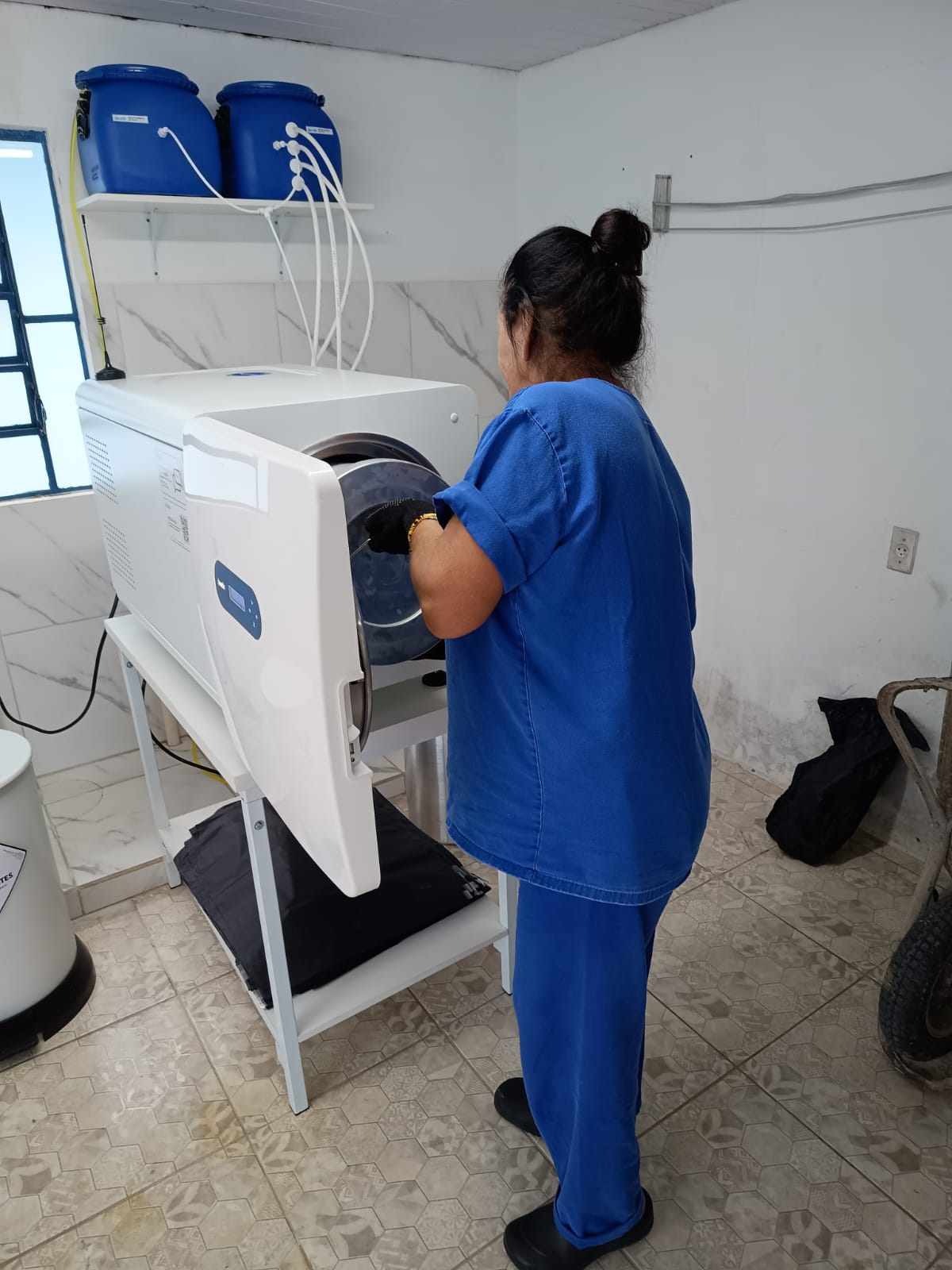

STERIALE-54 is an automatic autoclave that operates at high temperature and pressure, offering a rapid sterilization process using steam. With a capacity of 54 liters, it is designed for the sterilization of infectious biological waste. It should be used in conjunction with the special Steriale System supplies and containers.

Intended Use

This autoclave has been specifically designed for the sterilization of infectious biological waste in healthcare facilities. It is ideal for hospitals, clinics, laboratories and other medical centers that need to manage their waste safely and efficiently.

Certifications

- ISO 13485 – Quality Management System for Medical Devices

- RDC 16/2013 – GMP (Brazil)

- INMETRO – Instituto Nacional de Metrologia, Qualidade e Tecnologia (National Institute of Metrology, Quality and Technology) (Brazil)

Features

- Class B autoclave with vacuum pump and configurable pre-vacuum cycles.

- Internal chamber allows sterilization of one or more containers at the same time.

- Microprocessor control system with 16 programs, 9 of which are adjustable.

- LCD display with 2 lines x 16 characters showing temperature, pressure, time and error messages.

- Safety system that prevents the door from opening while the chamber is pressurized.

- Anti-vacuum valve that prevents the formation of vacuum inside the chamber during cooling.

- Stainless steel chamber and door.

- Automatic shutdown in case of excess temperature or pressure.

- Electronic cross-checking system that guarantees that the sterilization parameters (time, temperature and pressure) are reached simultaneously.

- Safety thermostat for heating element protection.

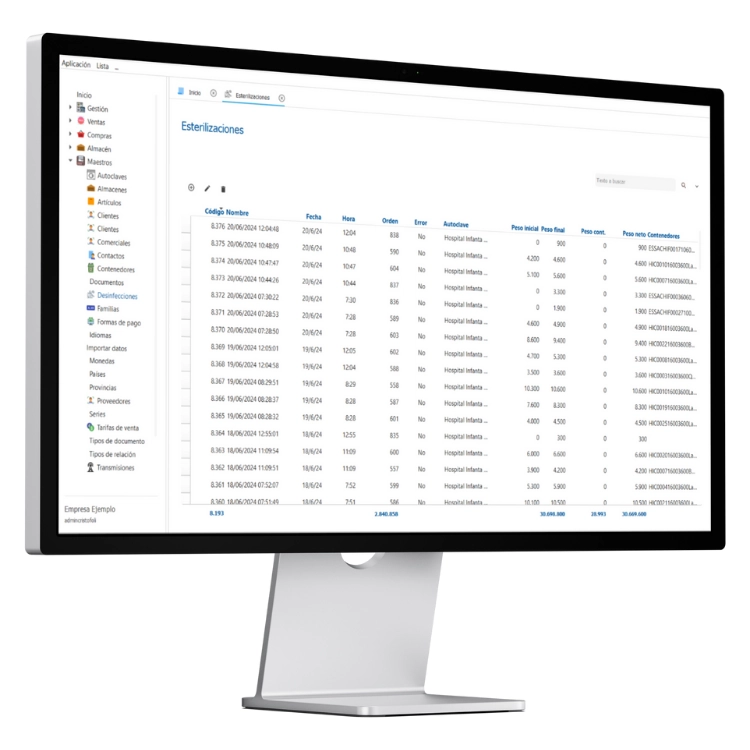

Steriale Application

- The GPRS module transmits all sterilization process data to the Steriale Software.

- The control system automatically records the date and time at which sterilization starts and ends.

- Includes SIM Card and SMA Antenna for internet connection.

Traceability

- High performance barcode scanner module with fast reading. It is capable of reading codes in low light or low resolution conditions.

- It can read ordinary barcodes, 2D barcodes and barcodes on mobile device displays.

HEPA filter

Air extraction system equipped with HEPA antibacterial filter.

Automatic Residue Weighing

High precision scale on the feet records the weighing of the waste before starting the cycle and also at the end of the cycle, allowing to identify how much weight has been lost during the cycle. All the information is sent to the Steriale Software.

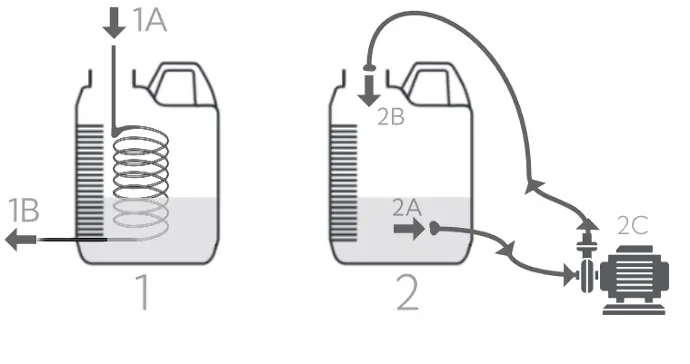

Installation of Water Tanks

The autoclaves need to be installed with 2 external water tanks.

- Tank 1 is the temporary waste tank, where the water discarded by the autoclave is first directed into the tank (1A), passed through a coil (heat sink) and then discharged directly to the appropriate municipal drain (1B).

- Tank 2 is the water recirculation tank for the vacuum pump. It is a water that must be changed every X days, defined during the installation of the system and notified to the health facility. This water is clean, obtained from reverse osmosis and enters through inlet 2A, feeds the vacuum pump (2C) and recirculates, returning to the tank again through outlet 2B.

Technical Information

| Volume | 54 Liters |

| Type | Class B |

| Chamber Size (W × H × D) mm | Ø340 × 660 |

| Overall Size (L × W × H) mm | 800 × 540 × 608 |

| Net Weight | 84,2 kg |

| Gross Weight | 89,5 kg |

| Power Supply | AC 230V ~ 50/60 Hz |

| Input Power (VA) | 3800 Watts – 1,6 kWh |

| Temperature Range | 134 ~137 ºC |

| Chamber Material | 304 Stainless Steel |

| Non-linear error margin of weight sensors: | ±0.05% R.O. |

| Display | LCD display with 2 lines x 16 characters showing temperature, pressure, time and error messages. |

| Operation | 4 keys |

| Door opening and closing method | Automatic Door |

| Digital Communication Method | GPRS Steriale system with SIM card or Wi-Fi. |

| QR Code Scanner | Integrated RS232 communication scanner |

| Weight Sensors | 4 units with full bridge connection |

| Antenna Connector Type | SMA |

| Steam Generator | Yes ✔ |

| Water Quality Detection System | Yes ✔ |

| Preconfigured sterilization cycles | Infectious Residues, Liquid Residues and Leak Test |

| Cargo Capacity | 1 Container of 45 Liters |

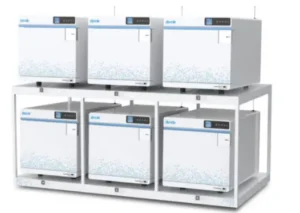

| Can be installed on double bedplate | Yes ✔ Example of a double bed installation |

| Safety Systems | Overcurrent protection fuses, electromechanical door switch, electronic temperature and pressure data cross-check system, electromechanical door motor lockout switch, electronic power control system, safety thermostat, sealing ring with pressure release at 3 kgf/cm² (294 kPa), on-screen warning message system, motorized door opening and closing mechanism, PSV (Pressure Safety Valve) for pressure relief in case of failure of electronic systems or if pressure reaches 2.8 kgf/cm². |

Sterilization Cycles

| Infectious Waste Cycle | Leak Test Cycle | Liquid Waste Cycle | |

|---|---|---|---|

| Intended use | Sterilization of mostly dry infectious biological waste. | Daily leak test to ensure that the autoclave does not leak. | Sterilization of mostly liquid infectious biological waste. |

| Total Time | 50 minutes | 15 minutes | 90 minutes |

| Sterilization Time | 8 minutes | 4 minutes | 10 minutes |

| Drying Time | 5 minutes | ~ | 5 minutes |

| Temperature | 134ºC | 134ºC | 134ºC |

| Pressure | 2.2 kgf/cm² 2.2 kgf/cm² 2.2 kgf/cm² 2.2 kgf/cm | 2.2 kgf/cm² 2.2 kgf/cm² 2.2 kgf/cm² 2.2 kgf/cm | 2.2 kgf/cm² 2.2 kgf/cm² 2.2 kgf/cm² 2.2 kgf/cm |

| All cycles come from the factory and can be configured to best suit the local legislation of each country or region. | |||