Presentation

The Compacting Machine from Steriale is the ideal solution to increase efficiency in the on-site treatment of infectious biological waste, i.e. within the hospital premises.

Used in conjunction with the other components of the Steriale System, it allows the Steriale telescopic containers to be compacted to 1/3 of their original size, facilitating the sterilization of more kilos of waste with less volume.

This innovative system contributes significantly to the safe and efficient management of hospital waste.

Intended use

The Compacting Machine is designed for the compaction of infectious biological waste operated with the Steriale System. The Steriale telescopic container is inserted into the machine, the door is closed, the start button is pressed, and the system begins compacting the waste.

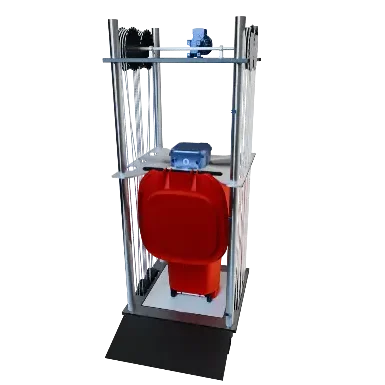

The Compacting Machine is designed with a robust rectangular structure, mainly made of stainless steel, which guarantees corrosion resistance and durability. It has a transparent acrylic front door that allows observing the compaction process in a safe way.

Its mobile platform, operated by means of high-strength nylon winches, supports loads of up to 40 kg. This facilitates efficient transport and storage of waste, reducing space by 60%. The compacted container is then taken to the Steriale autoclave for sterilization of its contents.

Features

- Safety system that prevents the equipment from operating if the door is not closed.

- Scale for weighing the container before sterilization (Full version).

- SIM-GPRS connection for data communication (Full version).

- QR reader included to facilitate the traceability of Steriale containers (Full version).

- It includes an easily accessible control panel, safety sensors and an electric drive system located at the bottom to optimize space.

- Compression capacity up to 60% of its original volume.

- Allows the compaction of infectious waste bags or low density and high volume waste directly deposited inside.

- Easy to operate, with safety devices to prevent industrial accidents.

Disinfection Mechanism

- HEPA filter

Available Colors

- Metallic Gray (Stainless Steel)

| Steriale Compacting Machine | ||

|---|---|---|

| Material | Stainless steel (ref. 304) | |

| Available Colors | Metallic Gray | |

| Motor power | 0.18 kW (0.24 HP) | |

| Operating voltage | 220 V | |

| Weight | 95 kg | |

| Particularities | Standard version:

| Full version:

|

| Safety Devices |

| |

| Electrical components |

| |

Dimensions

Maintenance

Frequency:

Visual inspection of sheaves, pulleys and welds every 6 months, lubrication of moving parts once a year and revision of the electrical system and sensors every 12 months.

Cleanliness:

Clean the machine with a damp cloth and mild detergent after each use, avoid using pressurized water directly on electrical parts.

Parts replacement:

Replace the wires or electrical components if they show signs of wear or damage and periodically check the condition of the sensors and electrical connections.